![]()

![]()

![]()

Bentley T-Series SBH13247,

delivered by

Richard

Treacy,

There are three well-known safety matters concerning Silver Shadow

series cars which have been hovering around since they were built. Those are the final drive torque arm on early

cars, the main steering pendulum lever on cars with steering boxes, and the

final drive crossmember. Decades ago I knew of the final drive crossmember and torque arm failures. I learned the hard way of the last failure

when the pendulum lever broke a few years ago on our T-Series, SBH13247, delivered

in

I have read many articles about the weaknesses in the torque arm and the

final drive crossmember, but was feeling smug because

ours had been modified back in the 1970s by the

Late last year, my father stopped the T-Series at the sign a block from

home in

What the hell was that ? The final drive crossmember had ripped out from the floor of the car. Safety issue No 4 had reared its ugly head, as subsequent research has shown that this particular failure is becoming alarmingly frequent as the cars age and fatigue.

The solution ?

Reinforce the boot floor and the small subframe

which together hold the final drive crossmember in

place. It’s better to do the strengthening before it

fails, and thereby save thousands in

peripheral damage to the exhaust, differential and half shafts to start with,

not to mention injuries in a probable crash.

The diagram shows the standard original unmodified arrangement in cross

section. Note that the load is taken by the boot floor and the small subframe fixed to the bodyshell.

The distance tube (item 2) holds it all firm. However,

the boot floor and the small subframe sections are

clearly too flimsy and failed through fatigue over time on our car and others.

Note also the mismatch in the diameters of the distance tube and the washers:

not good practice, especially with such small gauge metal. Since repairing our car, other owners have

been alerted. Fortunately, they have

discovered impending catastrophes and avoided them.

This is the piece of sheet metal which ripped out from the boot floor.

Note the complete absence of corrosion anywhere, but rusty cars will be at even

greater risk.

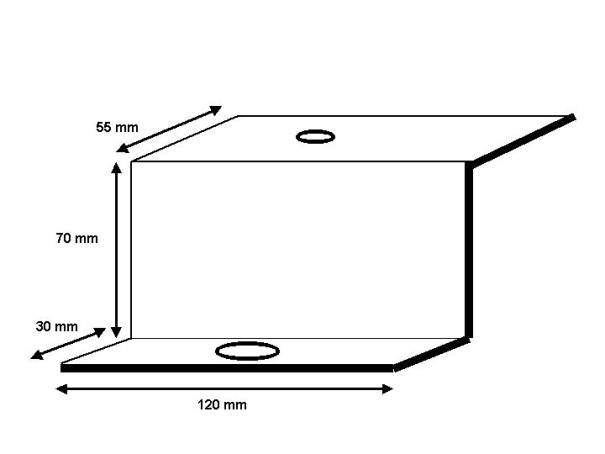

To reinforce the small subframe supporting the

final drive crossmember, we devised a Z-bracket. Its dimensions are shown in the sketch below,

but the 70 mm offset should be checked in each case. It is fabricated from 4 mm mild steel plate.

The Z-bracket is secured to the

boot floor by a small bolt purely to ensure that the final drive crossmember is correctly located during assembly, and sits

above the subframe silentblock

mounting. The two large washers (original) can be seen between the subframe and the mount centre left. One may be removed on each side if it makes

the half shafts straight, but that should be decided on a case-by-case basis.

There was no welding undertaken on the car. This decision was made so not to

introduce new stresses or fatigue sites. The repaired section was simply boxed

in to make it extremely sturdy. The Z-piece, the large washer plate in the boot

and the distance piece are all held firmly boxed together by the main final

drive crossmember mounting bolt. The whole

arrangement is held in very securely.

Here is the large 4mm washer plate in the boot. Both sides are modified

with washer plates and Z-pieces. The

washer on the right hand side should be profiled as the sheet metal steps at

the rear.

Below are two other incarnation of the boot

floor reinforcement. Clearly

just about anything will do.

So, back to the problem in the 1970s. Below is an unmodified final

drive crossmember.

If yours looks like this, just panic slowly.

Here is the final drive crossmember as modified in the late 1970s by the Sydney

Rolls-Royce distributor. Note the revised harmonic balancer mounts to Silver

Shadow II specification, and the through-bolts and distance tubes boxed in for

the silentblock mount. Compare that to the diagram in

the workshop manual in fig. 1. It is very much stronger as modified. Despite

this, a warning !! The final drive crossmember

was showing cracks despite this essential modification. We had it repaired,

strengthened and checked for straightness yet again by a subframe

specialist in the ACT. Apart from fabricating the Z-piece, this was the only

welding carried out. We used Nylock nuts on the new main bolts.

Below is a crossmember

modified recently in the

Just to prove that the beloved monster is back on the road.